- Search Site:

- +44 (0)1767 604710 |

info@smithsadvanced.com

We are a leading stockholder and global supplier of metals and plastics into Aerospace & Space, Chemical, Defence, Medical, MRO, Naval, Nuclear, Oil & Gas and Power industries.

We make high quality materials available in a fast, cost-effective and convenient package and provide a consistent supply path for all our customers.

Rene 41 nickel round bars offer exceptional strength at elevated temperatures.

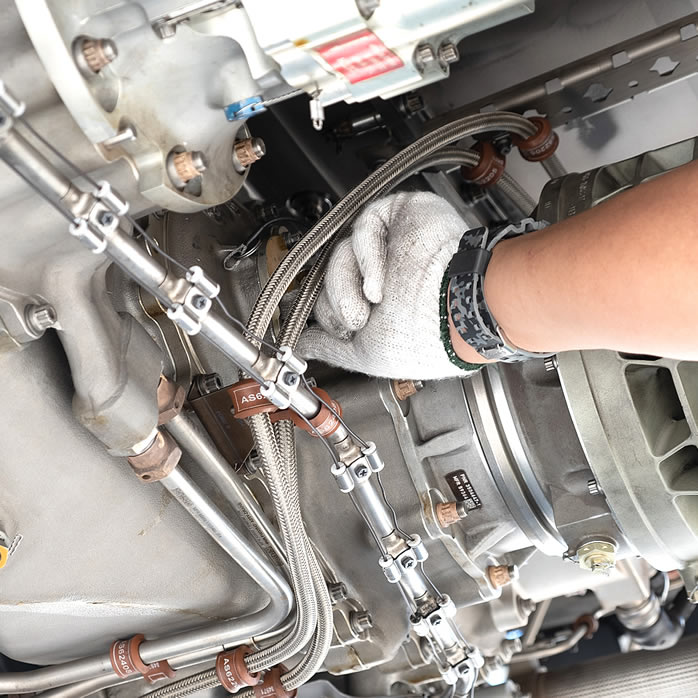

The alloy is highly corrosion and oxidation resistant and finds use in severely stressed high-temperature applications such as afterburners, rocket engines, aircraft engines and gas turbine components. Mechanical properties for the alloy may be tailored depending on the combination of cold work and/or heat treatments utilised.

We stock Rene 41 bars in various sizes and process them in-house to exact lengths to suit your engineering requirements.

AMS5712

AMS5713

UNS N07041

Gas turbines

Afterburners

Rocket engines

Aircraft engines

Excellent high-temperature strength

Excellent oxidation resistance

Good forming characteristics

Mechanical properties may be altered

You are currently here:

Materials / Nickel Alloys / High Temperature / Nickel Alloy Bars / RENE 41