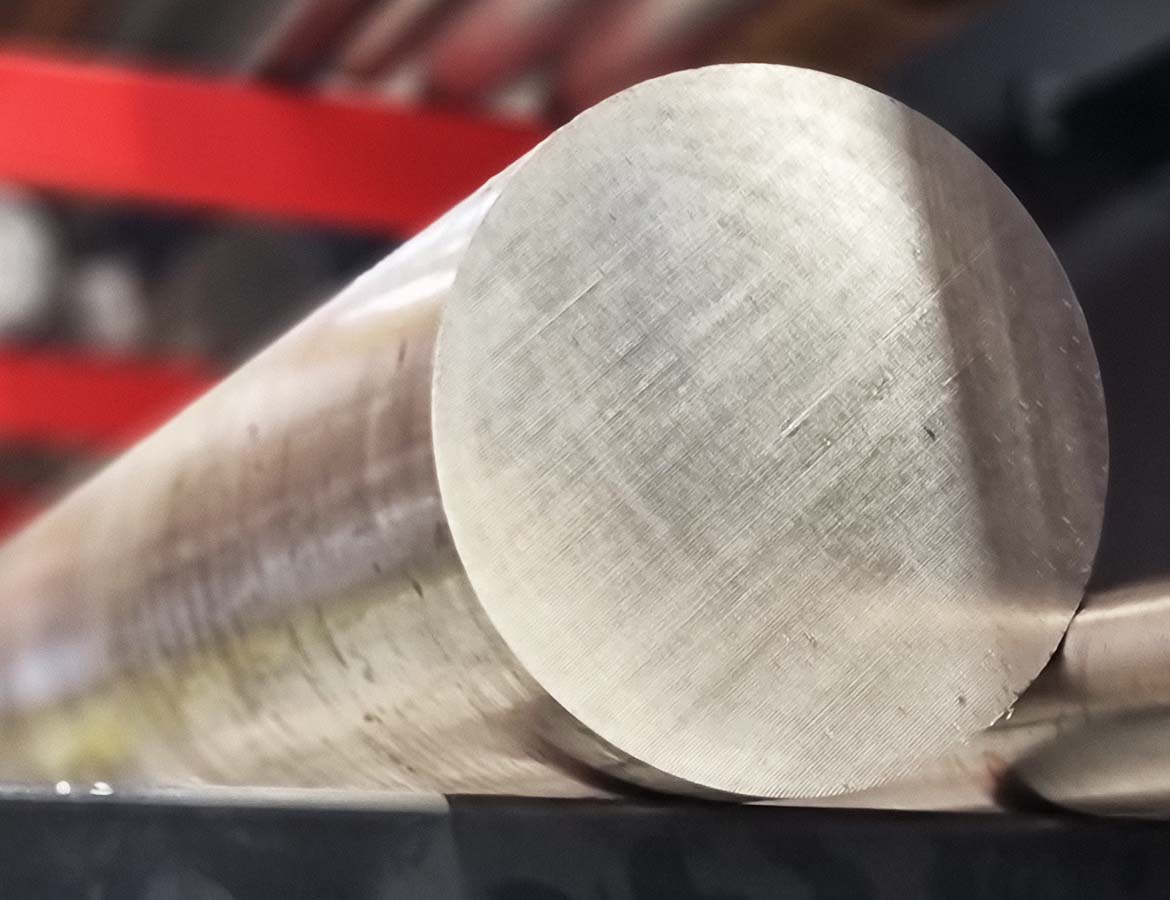

6-2-4-2 Titanium Bar

Near-alpha titanium alloy.

6242 Titanium bar is a near-alpha titanium offering outstanding performance characteristics to give designers improved options.

6-2-4-2 (6AL-2SN-4ZR-2MO) titanium alloy combines outstanding mechanical strength and stability. Creep resistance is also impressive, performing at temperatures as high as 538°C (1000°F). Machining and forging characteristics for the alloy are very similar to Grade 5 titanium (Ti-6Al-4V). These performance characteristics allow customers to create components that work effectively at much higher working temperatures. We stock 6-2-4-2 titanium bars in the annealed condition and in various sizes to suit your requirements.

For High Performance Applications

6242 titanium alloy finds use in high-performance applications throughout industry. The alloy is lightweight with excellent mechanical strength, which provides designers and engineers with options, particularly in market sectors such as motorsport and aerospace. Strength to weight ratios are critical in these markets, and both titanium and aluminium feature heavily in the manufacture of high-performance components and structures.

Commercial Applications

6242 titanium bar is a high-performance engineering alloy and finds use in engineering applications, including motorsport components, gas turbine engines, impellers and aerospace structural parts.

Company Ethos

We offer high-quality materials quickly, cost-effectively, and conveniently while providing a consistent supply path for all our customers

Discover- AMS 4975

- AMS 4976

- MSRR8662

- 3.7144

- 6Al-2Sn-4Zr-2Mo

- UNS R54620

- Gas turbine engines

- Aerospace structural components

- Motorsport components

- Impellers & turbines

- Outstanding mechanical strength

- Impressive creep resistance

- Good machinability

- High toughness