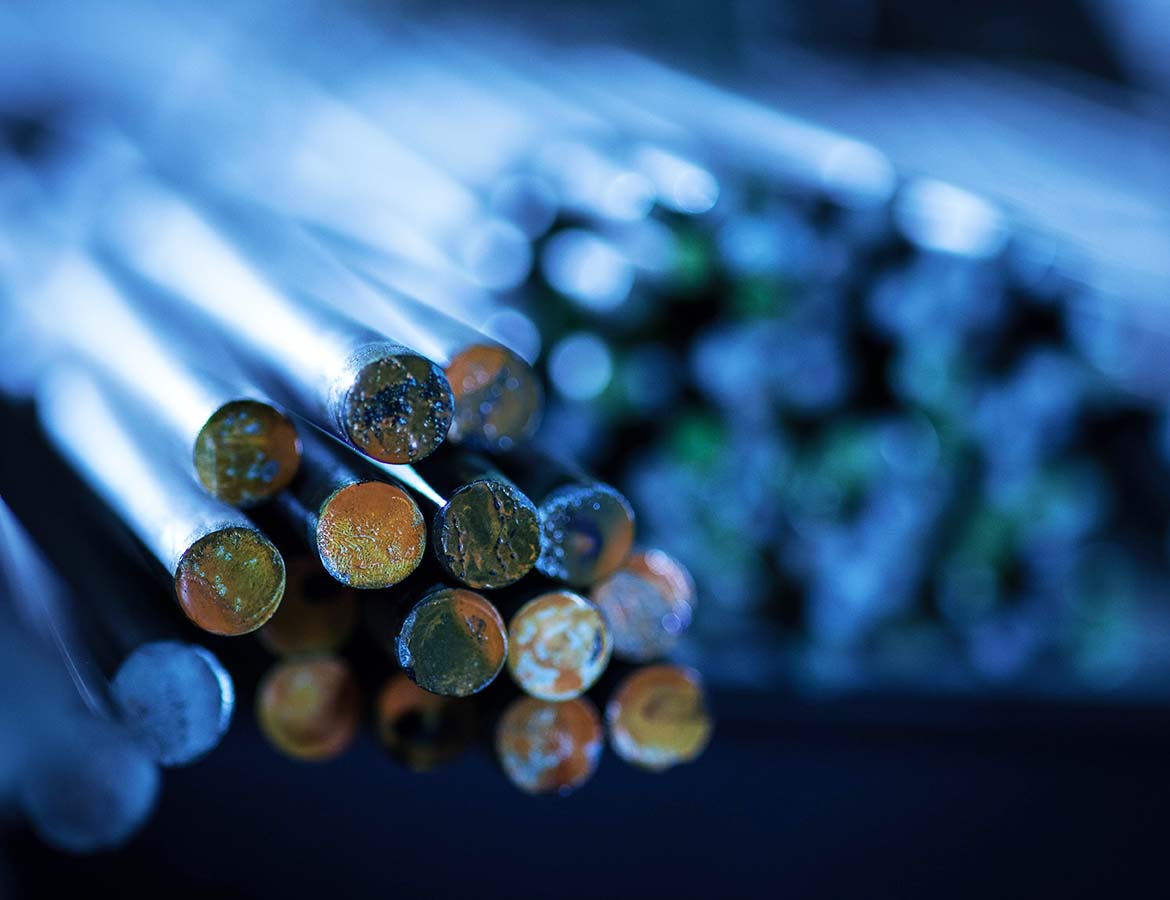

BS S130 Stainless Steel Bar

Non-magnetic, austenitic stainless steel.

We stock BS S130 austenitic stainless steel bars, which offer good resistance to atmospheric attack.

BS S130 is an austenitic 18% chromium and 9% nickel and a BS aerospace grade stainless steel. The alloy is niobium stabilised to overcome the risk of intergranular corrosion, typical of certain stainless steels after exposure to temperatures of 430 to 820°C. The material is non-magnetic and cannot be hardened by subsequent heat treatment. With good formability and cold working characteristics, BS S130 offers a machinability rating of approximately 36% (with 1212 rated at 100%). Adding niobium prevents sensitisation (weld decay) and may be welded by most standard methods except forge and hammer welding. Post-weld heat treatment is not required with this alloy.

Corrosion Resistance

With high corrosion resistance, the alloy also offers good oxidation resistance. The material is particularly suited to welded structures and finds use in aerospace components and fasteners, nuclear components and food processing applications.

Stock Availability

We supply BS S130 stainless steel bars in various sizes and stock the material in the solution treated condition. We also process your stainless steel bars in-house via our dedicated bar cutting service.

Ultrasonic Inspection

As part of our commitment to quality, we offer ultrasonic inspection services which accurately test your materials for hidden defects.

Discover- 1.4546

- 347S31

- AISI 347

- AMS 5646, AMS QQS 763

- ASTM A276, ASTM A479

- BS S100, BS S130

- MSRR6522

- UNS S34700

- X5CrNiNb18-10

- Fasteners

- Nuclear components

- Aerospace components

- Food processing applications

- Good formability

- Good resistance to atmospheric corrosion

- Good weldability

- Resists intergranular corrosion