Alloy 263

Nickel Cobalt Based Alloy Sheets

Alloy 263 contains nickel-cobalt-chromium-molybdenum alloy, which has excellent mechanical properties after aged hardening.

Our nickel-cobalt sheets are highly versatile, providing many attractive performance characteristics. High-temperature strength and corrosion resistance are synonymous with this alloy, and impressive welding and forming capabilities, particularly by cold working. Oxidation resistance is outstanding, and although Alloy 263 is not the best corrosive-resistant alloy, being so easily formed and welded makes it an attractive material proposition. We supply Alloy 263 in the annealed condition, which provides excellent ductility.

Commercial Applications

Although the alloy was developed specifically for the aerospace market, its chemical and mechanical properties lend themselves to various engineering markets and applications, some of which are highly specialised. For example, Alloy 263 is useful in advanced ultra-supercritical power plants (A-USC). Other applications include aircraft engine casings, gas turbine rings and combusters.

Performance

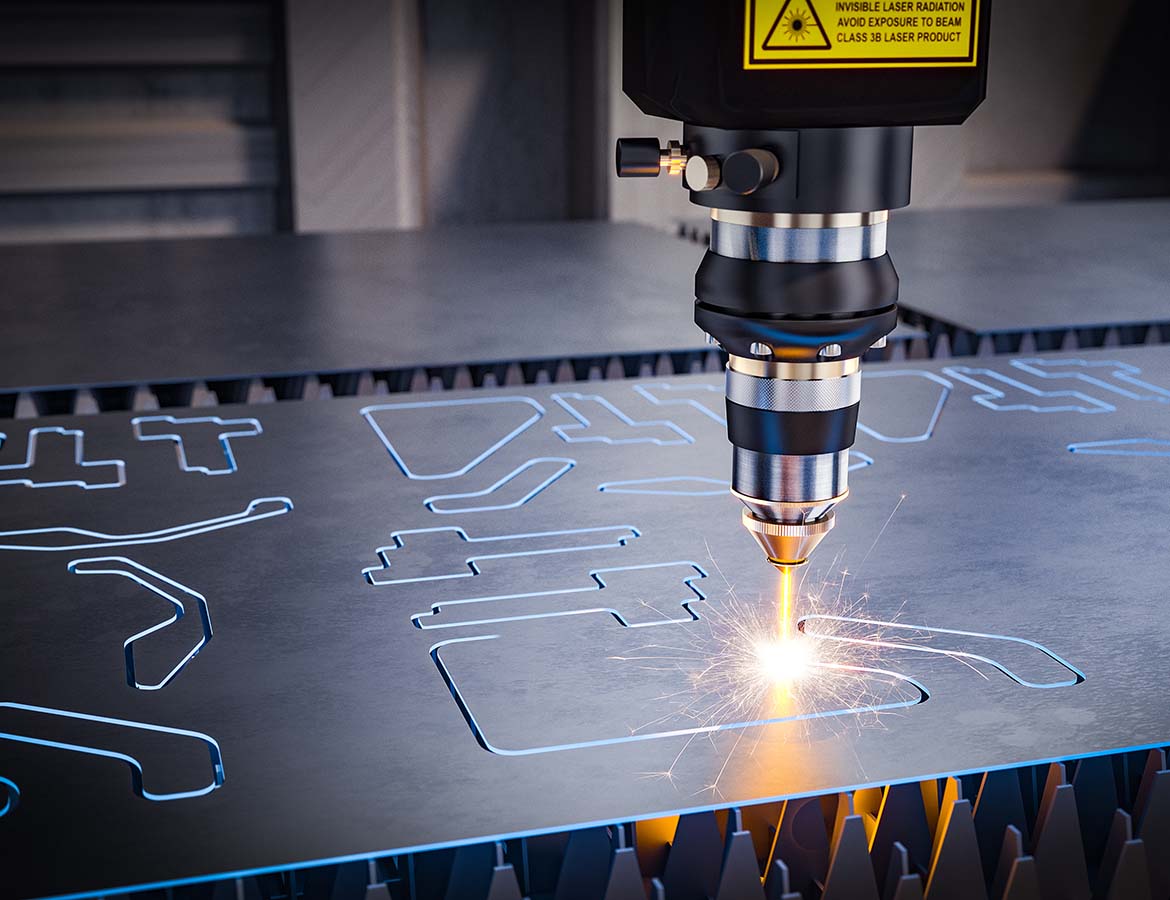

The alloy's material strength is retained up to 816°C and oxidation resistance up to 982°C. We supply Alloy 263 nickel cobalt sheets in the annealed delivery condition. We also provide in-house cutting services, using guillotines to cut your nickel cobalt sheets to tight tolerances before shipping.

Total Visibility

Our bespoke supply packages provide customers with 24/7 access to 'live' stock information.

Discover- Alloy 263

- N07263

- 2.465

- AMS 5966, 5886, 5872, 5872E

- RRMS 33031/1 (MSRR7035)

- BS HR10

- Gas turbine rings

- Aircraft engine casings

- Advanced Ultra-Supercritical Power Plants (A-USC)

- Sealing rings

- Simple to form and weld

- Excellent ductility in the annealed condition

- High-temperature strength

- Excellent oxidation resistance