RENE 41 Nickel Bar

Excellent oxidation resistance.

Rene 41 nickel round bars offer exceptional strength at elevated temperatures.

Rene 41 is a nickel-based high-temperature alloy with high strength at temperatures ranging from 649 to 982°C (1200 to 1800°F). It is marketed under various names, including Udimet Alloy® R41 and Haynes® R-41. The material is a precipitation-hardenable nickel-chromium alloy with titanium and aluminium additions to promote high strength.

Corrosion Resistance

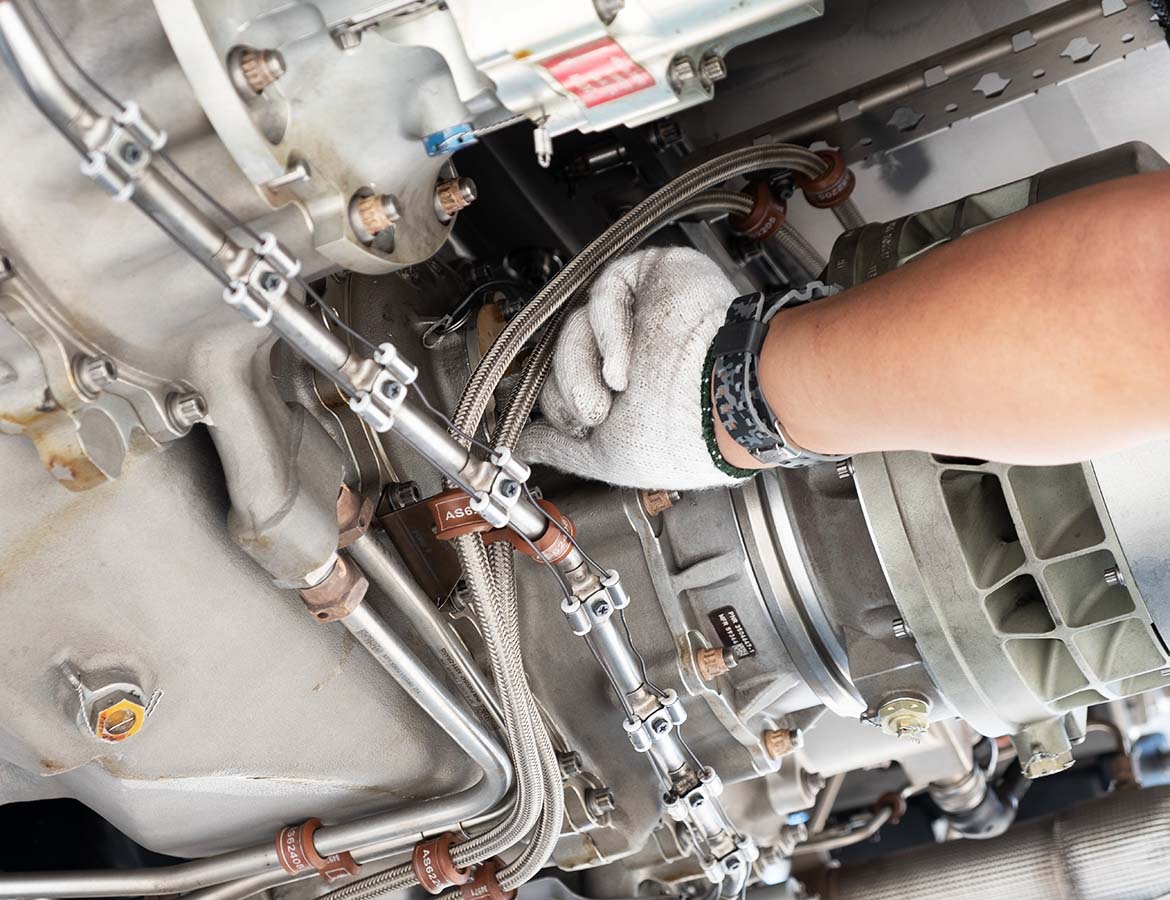

The alloy is highly corrosion and oxidation-resistant and is used in severely stressed high-temperature applications such as afterburners, rocket engines, aircraft engines, and gas turbine components. The alloy's mechanical properties may be tailored depending on the combination of cold work and/or heat treatments utilised.

Stock Availability

We stock Rene 41 bars in various sizes and process them in-house to exact lengths to suit your engineering requirements.

Ultrasonic Inspection

As part of our commitment to quality, we offer ultrasonic inspection services which accurately test your materials for hidden defects.

Discover- AMS 5712

- AMS 5713

- UNS N07041

- Gas turbines

- Afterburners

- Rocket engines

- Aircraft engines

- Excellent high-temperature strength

- Excellent oxidation resistance

- Good forming characteristics

- Mechanical properties may be altered