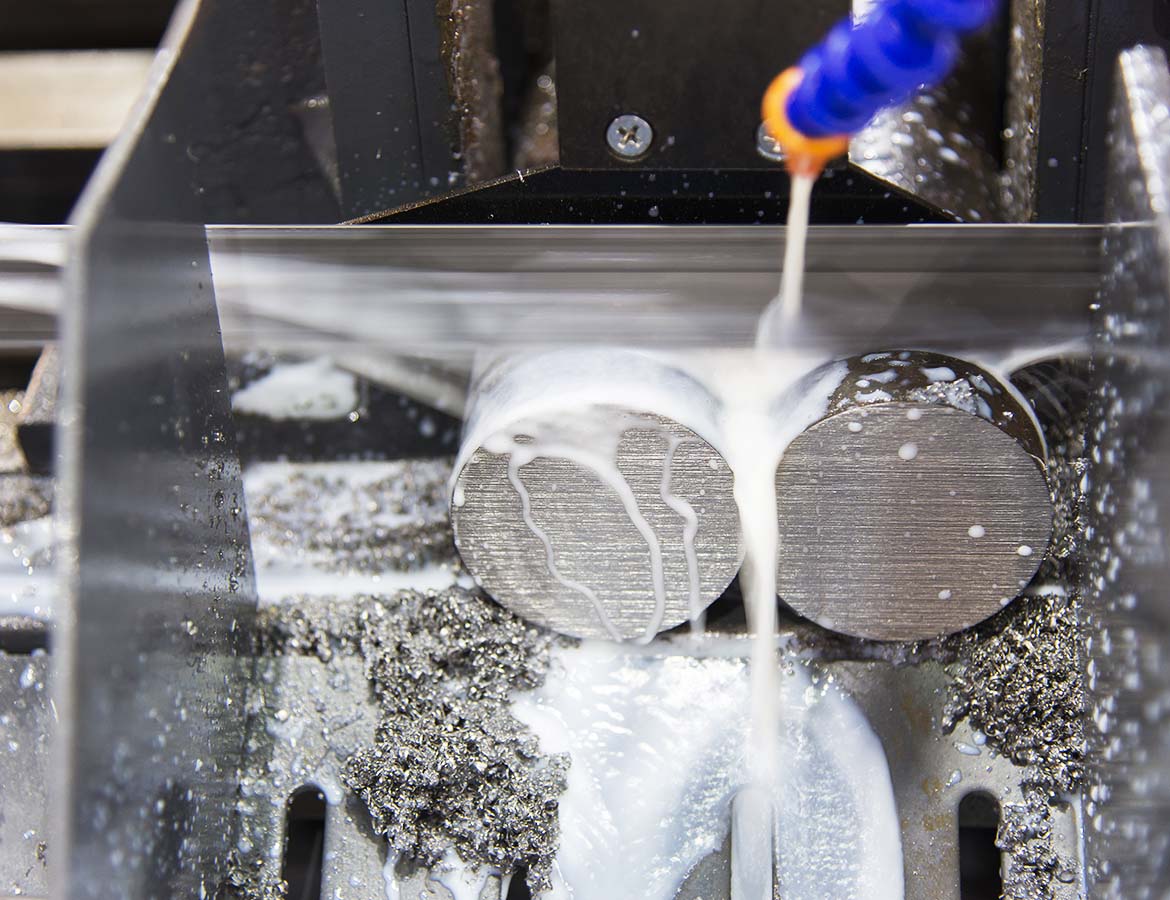

Bar Cutting / Rod Blanking

Processing Services

With over 2 million billets cut at our warehouse per year, our ISO 9001-approved rod blanking service will cut bars to more manageable sizes.

If you are purchasing your raw materials in full bar lengths to cut them down to more manageable billets, our rod blanking options may be worth considering. The high volumes and scale we process our bar stock enable us to scale efficiencies that reduce our cutting costs to a minimum, and we pass these efficiencies on to our customers. We have no minimum processing quantity and will process even down to one blank. We also offer pin marking and chamfering as part of our bar-cutting service.

Get Ahead

Component manufacturing processes often begin with many simple, repetitive cutting operations. By utilising our additional processing services, you can free up your skilled workforce and their machines to concentrate on the part of your manufacturing process that adds value. Our in-house processing operations promote cost savings for your business from reduced scrap, paperwork, and inspections. In many cases, machinery costs can even be reduced.

Contact Us Today

At SSmiths Advanced Metals, we are proud to be a leading international, multi-metal alloy stockholder and distributor. Contact us today and let Smiths Advanced Metals help you with your metal project.

Market Specific

We stock products to support specific target operating markets and their engineering applications.

Discover- Min: ½" (12.70mm)

- Max: 21¼" (539.75mm)

- ± 0.03"

- ± 0.762mm

- ½"

- 12.70mm