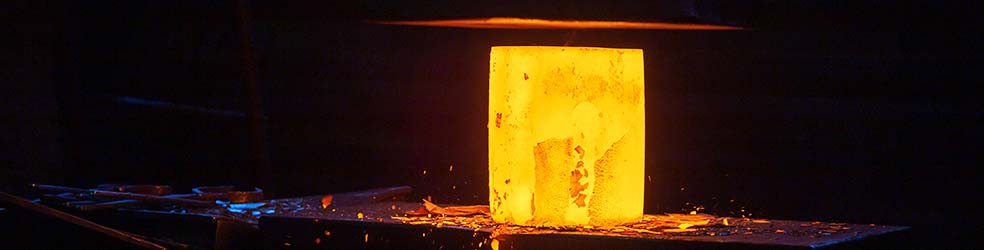

Elevated & Cryogenic Temperature Performance

Extreme Environments

Our high-temperature alloys perform in some of the world's most demanding operating environments.

Whether you are looking for alloys that perform well at elevated or cryogenic temperatures, we stock a range of predominantly nickel alloys that offer the required performance characteristics.

Alloys

Our nickel-based stock range introduces alloying elements, which change the performance characteristics depending on the particular grade in question. In the alloying process, introducing titanium, tantalum or niobium impacts the material's overall strength and heat resistance.

Extreme Environments

Nickel alloys combine corrosion resistance, oxidation resistance, and mechanical strength, resulting in highly suitable products for extreme operating environments.

View Range

High Melting Point

Nickel alloys have a very high melting point of 1453°C.

Overall heat resistance will vary depending on additions in the alloying process. Still, any nickel-based alloy will offer a high degree of temperature resistance. Alloying elements include copper, chromium, molybdenum, iron, titanium and cobalt.

Our high-temperature alloys are nickel-based and suitable for the harshest environments.

Stock Portfolio

Our heat-resistant alloy stock covers a broad selection of material grades and specifications. Our primary stockholding includes nickel-based alloys with a very high melting point.

We offer high-temperature alloys in various shapes, including round bars and sheets available to customers on an ex-stock basis.

We combine our stock, in-house processing services, and UKAS accredited metallurgical support services to offer a single supply source for your engineering raw materials.