UNS C71500 Copper Nickel Bar

Improved strength

UNS C71500 copper nickel bars (also called cupronickel) include 30% nickel, providing greater strength.

The alloy is a direct equivalent of copper-nickel 70/30, including traces of iron and manganese in the alloying me to increase corrosion resistance. UNS C71500 offers medium to high strength and excellent corrosion resistance, making the product highly suitable for various commercial engineering applications. The alloy is similar to UNS 70600 but with improved strength characteristics.

Engineering Benefits

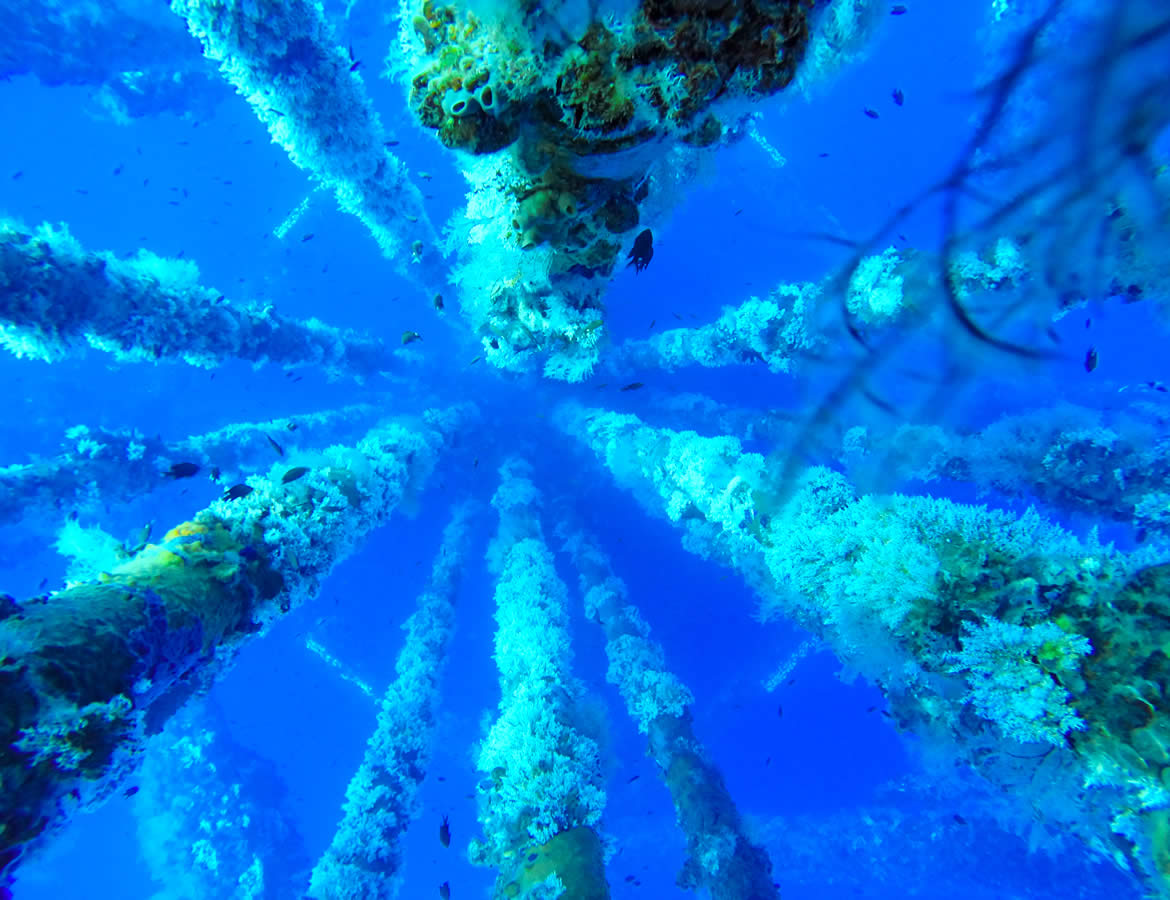

The material promotes good creep resistance at elevated temperatures and is straightforward to machine, weld, and form. However, the main benefit of UNS C71500 is the alloy's resistance to corrosion in marine atmospheres. The product is suitable for various applications in the above-sea and subsea engineering sectors, including condenser tubes, pipework, flanges, valves, and pump components.

Performance

Like similar products in this range, UNS C71500 offers superior corrosion and biofouling resistance in saltwater environments. The alloy also promotes resistance to chloride stress corrosion cracking. The alloy's antimicrobial characteristics make the product ideal for sanitised operating environments, such as hospitals, clean rooms, and food preparation areas.

Stock Availability

We stock UNS C71500 copper nickel in solid round bars to ASTM B151 and offer in-house processing where we cut your bars to specific lengths before shipping.

Total Visibility

Our bespoke supply packages provide customers with 24/7 access to 'live' stock information.

Discover- UNS C71500

- CW354H

- DEF STAN 02-879 Annex B

- DEF STAN 02-780

- NES 780

- Saltwater condensers

- Flange, valve and pump component

- Water boxes

- Heat exchangers and pressure vessels

- Medium to high tensile strength

- Excellent corrosion resistance in marine atmosphere

- Excellent anti-microbial capabilities

- Easily welded, machined and formed