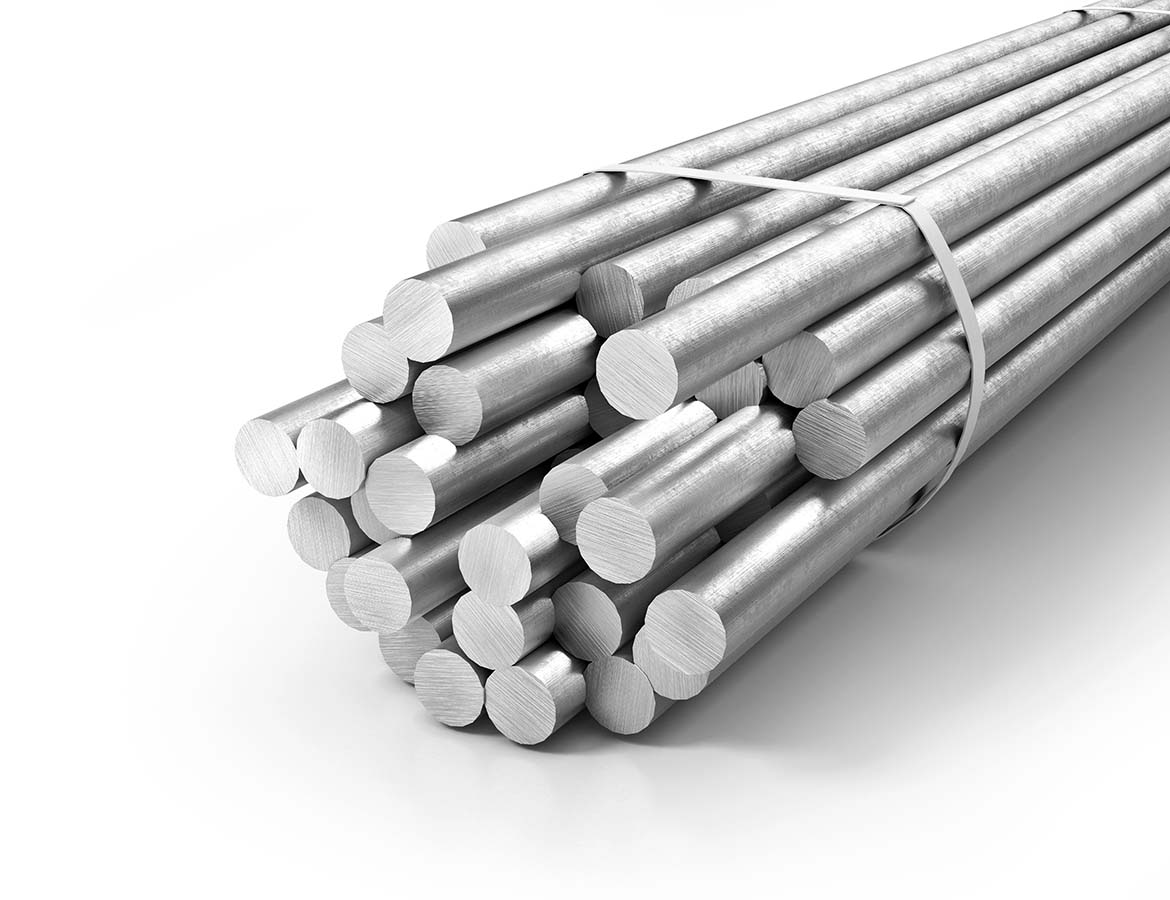

Our Titanium Bar Stock

Light, yet strong

Our low-density titanium bars offer the best strength-to-weight ratio, high corrosion resistance, and durability.

We stock titanium bars in commercially pure and alloyed grades that provide options for various engineering applications. Our product offers an excellent light-weighting solution in sectors such as aerospace and motorsport.

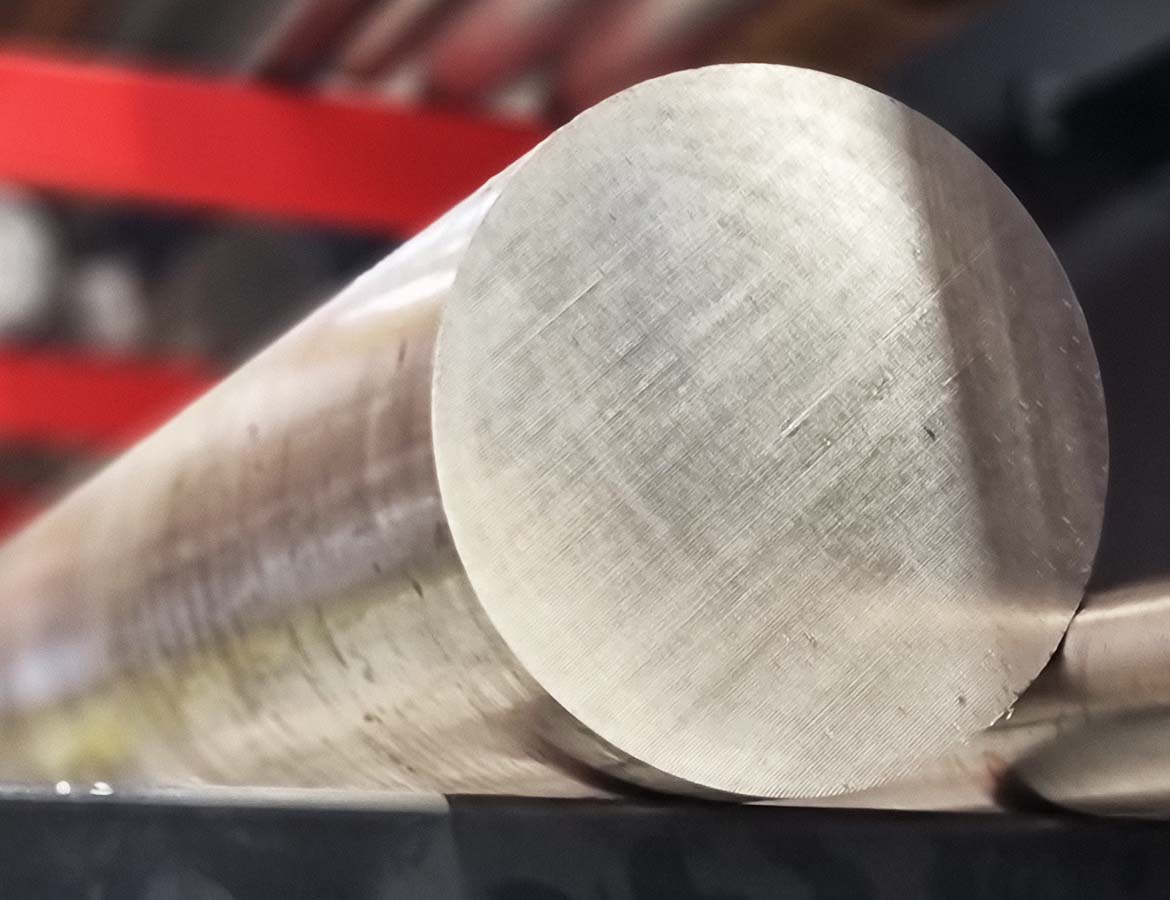

Rod Blanking

Our rod blanking service processes your titanium round bars to specific lengths. We perform these cutting operations in-house at our central warehouse in Biggleswade. Our warehouse accurately processes more than 2 million billets every year. We also supply titanium bars as standard lengths.

Use in Aerospace

Our titanium bars are particularly popular in the aerospace industry, where they are used in engineering applications such as aerostructures, aircraft engines, and propellers.

View Range

Reducing Costs

Utilising titanium in aerospace structures reduces the cost of production and saves weight without compromising strength.

Titanium has replaced aluminium and steel in various aerospace applications, including structural frameworks. Its strength and lightness provide superior performance while withstanding high temperatures.

Other titanium aerospace applications include landing gears, flap tracks and fuselage parts.

Stock Information

Our titanium bar stock includes multiple material grades, which offer different performance characteristics and find suitability in various commercial markets.

All our titanium bar stock carries a unique bar code for total traceability while under our care. Our barcode functionality forms part of our industry-leading bespoke IT platform.

We combine our stock, in-house processing services, and UKAS-accredited metallurgical support services to offer a single supply source for your engineering raw materials.