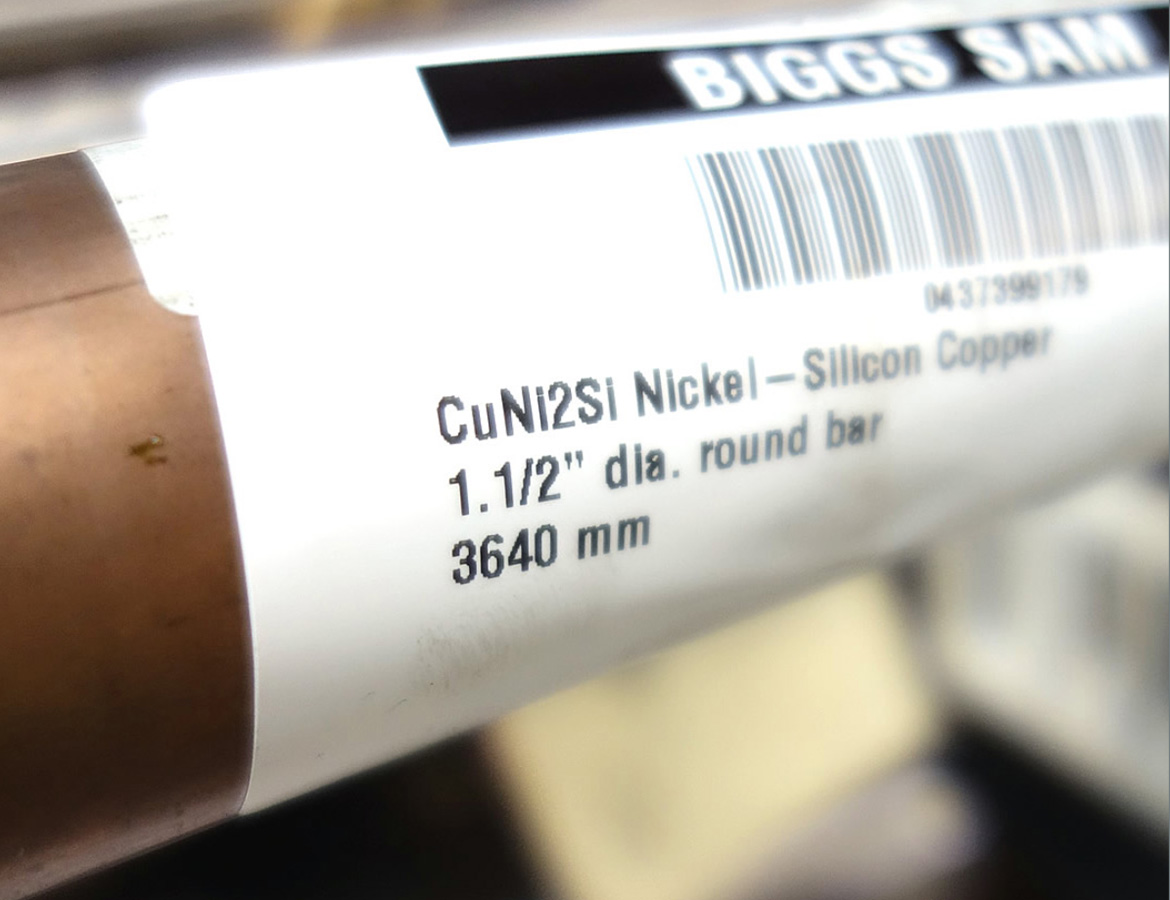

CuNi2Si Copper Bar

Superior when compared to other copper alloy grades.

CuNi2Si copper bars offer unique chemistry and mechanical properties.

CuNi2Si (CW111C) is a copper-nickel silicon alloy with unique chemical and mechanical characteristics. It is a superior product compared to othercopper alloy grades; the material promotes many beneficial performance qualities that virtually any engineering or fabrication company can benefit from. The material's corrosion resistance is excellent and surpasses that of most copper alloys while also being free from the effects of stress corrosion and hydrogen embrittlement.

Other Qualities

Wear and bearing characteristics are also superior, and the material benefits from high strength and hardness. Compared to non-ferrous alloys, CuNi2Si has excellent thermal and electrical conductivity. This alloy provides exceptionally low magnetic permeability, outstanding performance in cryogenic environments, and spark resistance.

Key Applications

CuNi2Si copper bars find typical use in cryogenic storage tanks, electrical components and engine valve guides & seats.

Export Services

Our export team is well-versed in global shipping, whether by land, sea, or air, ensuring your international orders are handled with utmost care and efficiency.

Discover- 2.0855

- CW111C

- UNS SC64700

- ASTM B411

- DIN 17666

- EN 12163

- Engine valve guides and seats

- Cryogenic storage tanks

- Electrical components

- Heat exchanger tubes

- High thermal & electrical conductivity

- Exceptionally low magnetic permeability

- Outstanding performance at cryogenic temperatures

- Non-sparking