Tough &Resilient

For aerospace components

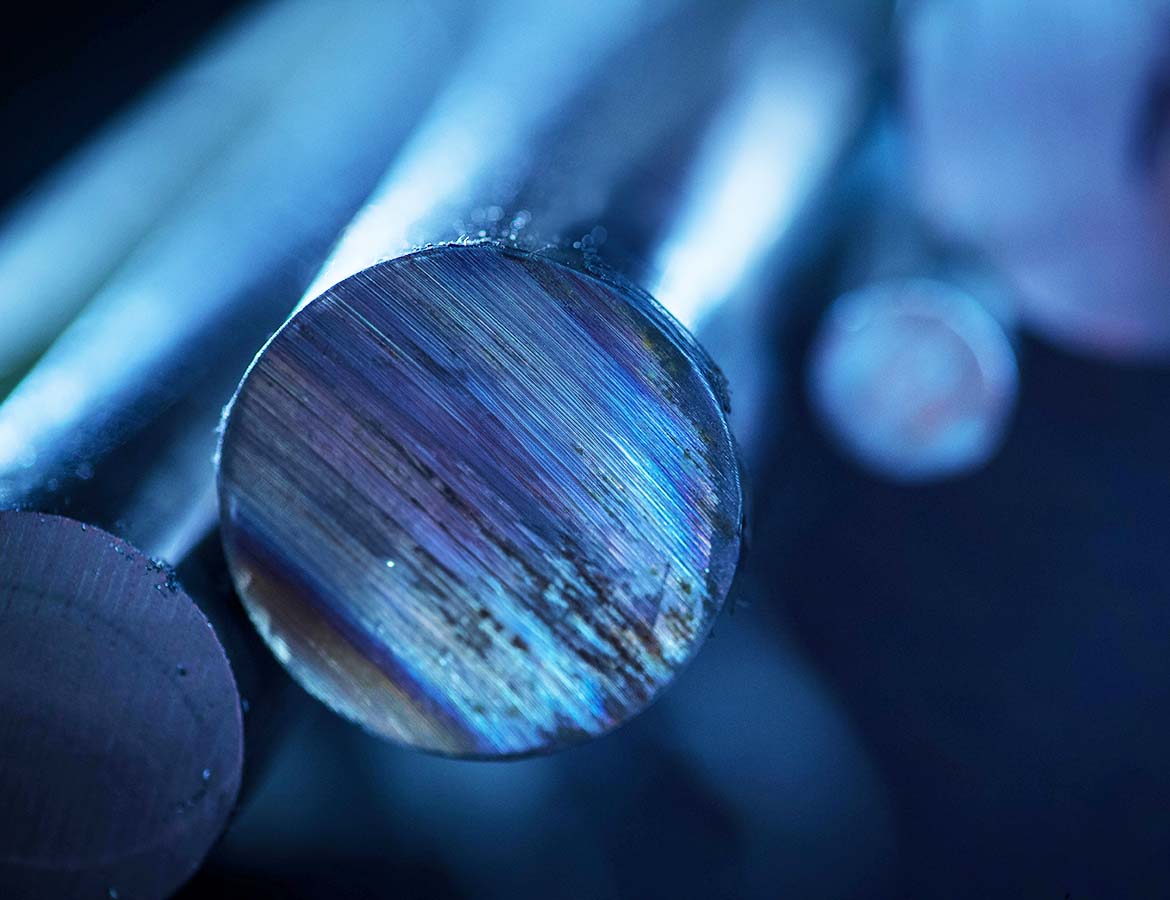

While steel is not the best lightweight solution for aircraft manufacturing, it remains a critical engineering raw material for aerospace applications.

The toughness and resistance to continual wear, combined with the material's ability to withstand stresses and impact, ensure that steel forms an integral part of any aircraft build. While aluminium is the product of choice for improved strength-to-weight ratios, steel is ideal for critical applications.

Use in Landing Gear

Aircraft landing gear is a prime example - steel's ability to withstand fatigue and stress makes it highly suitable, and we stock material grades for such use.

Further Examples

Our aerospace-grade steel bars are also used in applications such as engine components, exhaust ducts, and fuel tanks.

View Range

Long Lasting

The durability of steel makes it ideal for use in particular aerospace applications.

Commercial airlines need their aircraft fleet to be in continual service. The cost implications of aircraft not in service are severe and dramatically impact operating costs. Aerospace steel is durable and offers a long service life.

When a part's service life ends, an MRO supply business issues timely replacements. An example of such a company is Smiths MRO, a dedicated division of Smiths Advanced Metals.

Stock Information

We offer multiple aerospace steel bars to British Aerospace standards in various sizes to suit your needs.

Our sophisticated, bespoke MRP system ensures our customers have a high level of stock certainty.

We provide in-house bar cutting services at our bulk central warehouse located in Biggleswade, Bedfordshire.