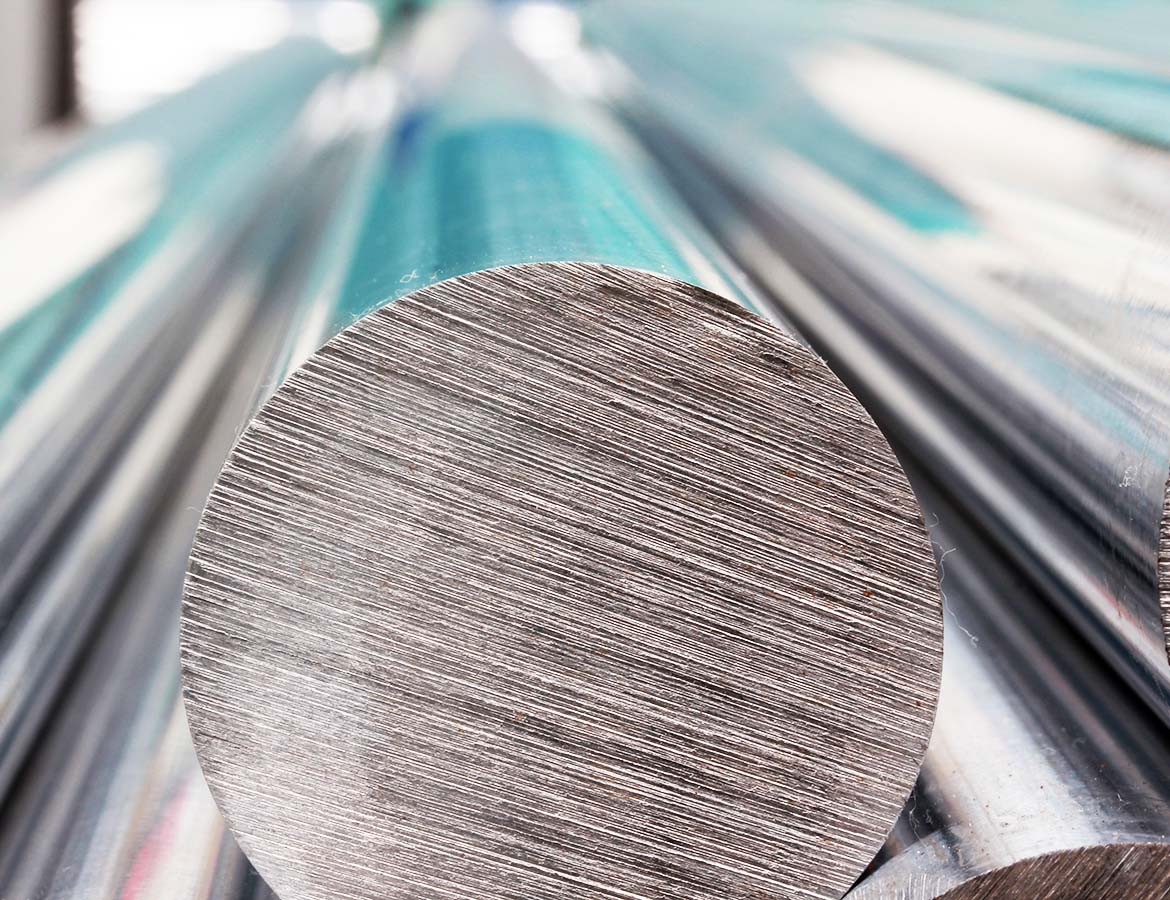

9310 Steel Bar

High hardenability.

9310 steel bar is a case-hardening steel regarded as a premium carburising steel alloy.

Alloy 9310 combines high fatigue strength with high core hardness. The low-alloy product offers high hardenability and is particularly useful in high-core strength applications, especially in aerospace. 9310 is a nickel-chromium-molybdenum alloy that offers good strength and toughness. The material is suitable for machining in the normalised, tempered state. The alloy's performance characteristics improve further after annealing, with better ductility and machinability. 9310 also promotes excellent transverse properties.

Commercial Applications

The product is used in engineering applications such as aircraft and helicopter parts, clutches, heavy-duty gears, and shafts.

About Carburising

Carburising is a type of heat treatment process performed on low-carbon steels to enhance the alloy's strength, hardness, and wear characteristics. Treatment time and temperature dictate how much carbon is absorbed by the steel and how hard, strong and wear-resistant the resultant alloy will be.

Stock Availability

Smiths Advanced Metals stocks 9310 steel bars in the normalised and tempered condition and in closer incremental sizes to suit your particular engineering requirements.

Market Specific

We stock products to support specific target operating markets and their engineering applications.

Discover- 299-947-032

- AMS 6260

- AMS 6265

- AMS 6267

- MIL-S-7393

- UNS G93100

- Heavy-duty gears

- Clutches

- Helicopter parts

- Shafts

- Excellent transverse properties

- High hardenability

- High fatigue strength

- For high core strength applications