Stainless Steel Alternative

Improving Performance

Nickel cobalt alloys are an excellent alternative to stainless steel in applications where particular stainless steel grades do not offer enough performance.

Our nickel cobalt alloy range operates in extreme environments thanks to an impressive balance of chemical and mechanical properties. Heat resistance, high-temperature strength, corrosion resistance and toughness are generally superior. Nickel cobalt also benefits from excellent forming capabilities, and welding is straightforward.

Commercial Appeal

Industries such as oil, gas, petrochemical, and aerospace have application areas where hot gases are present, and often, these applications are in critical structures. Aircraft engines, afterburners and gas turbine engines all fit into this category. Engineering materials need to be robust enough to meet the demands of these applications.

Meeting Needs

Nickel cobalt alloys offer the necessary performance attributes to meet such stringent demands.

View Range

Tweaking Characteristics

Engineering alloys are developed with chemistry and mechanical properties to meet specific applications.

Many product's characteristics can be tweaked either by slightly altering the chemistry in the production phase or by subsequent heat treatment and finishing.

Many customers are happy with an 'off the shelf' purchase, although high-technology businesses often seek greater sophistication.

Product Information

Nickel cobalt alloys offer high-temperature resistance and excellent corrosion resistance combined with high strength and toughness.

Our stock range is highly suitable for service in harsh operating environments such as gas and aerospace engines and afterburners.

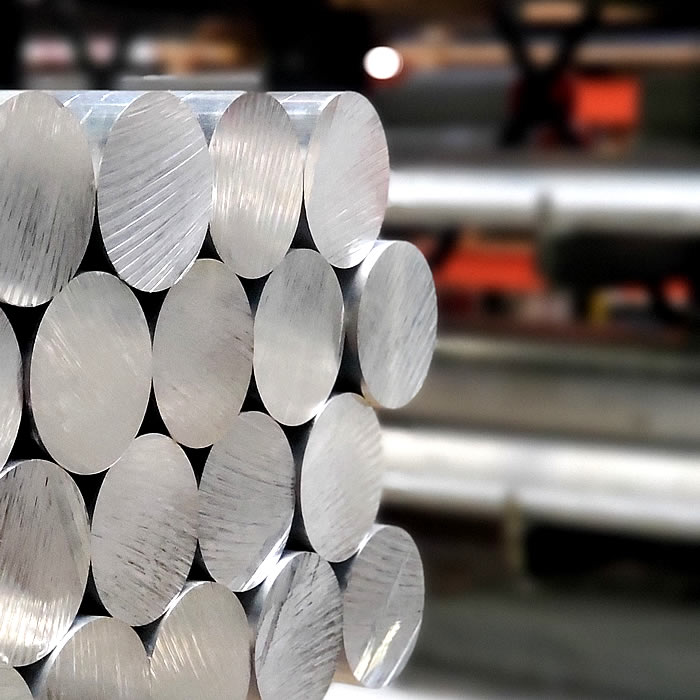

We carry extensive stock in various grades and forms, further supported by processing services to cut your products to exact sizes.